Design Concept

GX-Taurus laser welding machine is suitable for welding all metal materials, the welding speed is 3-10 times that of traditional argon arc welding and plasma welding, the welding heat affected area is small, and it is not easy to deform. The penetration is large, and the weld is beautiful and firm.

MAX Laser Source

MAX Laser Source,excellent beam quality and high stability, which structure is compact and water-cooling. The laser can be adjusted continuously, and the beam is transmitted be fiber and QBH connector, which is ideal for laser cutting, laser welding, etc .

ReIFar Control System

ReIFar laser welding cleaning cutting three-in-one system is the latest to launch a handheld laser welding, laser cleaning, laser cutting three-in-one integrated system. The working mode can be switched freely according to different application scenarios, providing diversified solutions for different application requirements of users.

ReIFar Laser Head

High-threshold optics for better welding results.

Multiple safety locks, higher security.

Intelligent protection system, mobile terminal App and PC monitoring, real-time feedback of working status.

Ergonomically designed, comfortable to hold, lighter in weight and easy to hold.

S&A Water Chiller

Water cooler, dual temperature and dual control, circulating water circuit, fast cooling laser source and welding head.

Technical Parameters

| Model |

GX-Taurus |

| Laser Source |

1000W/1500W/2000W |

| Laser Wavelength |

1070NM |

| Output Power Stability |

±2% |

| Power Requirements |

220V |

| Machine Power |

≤10KW |

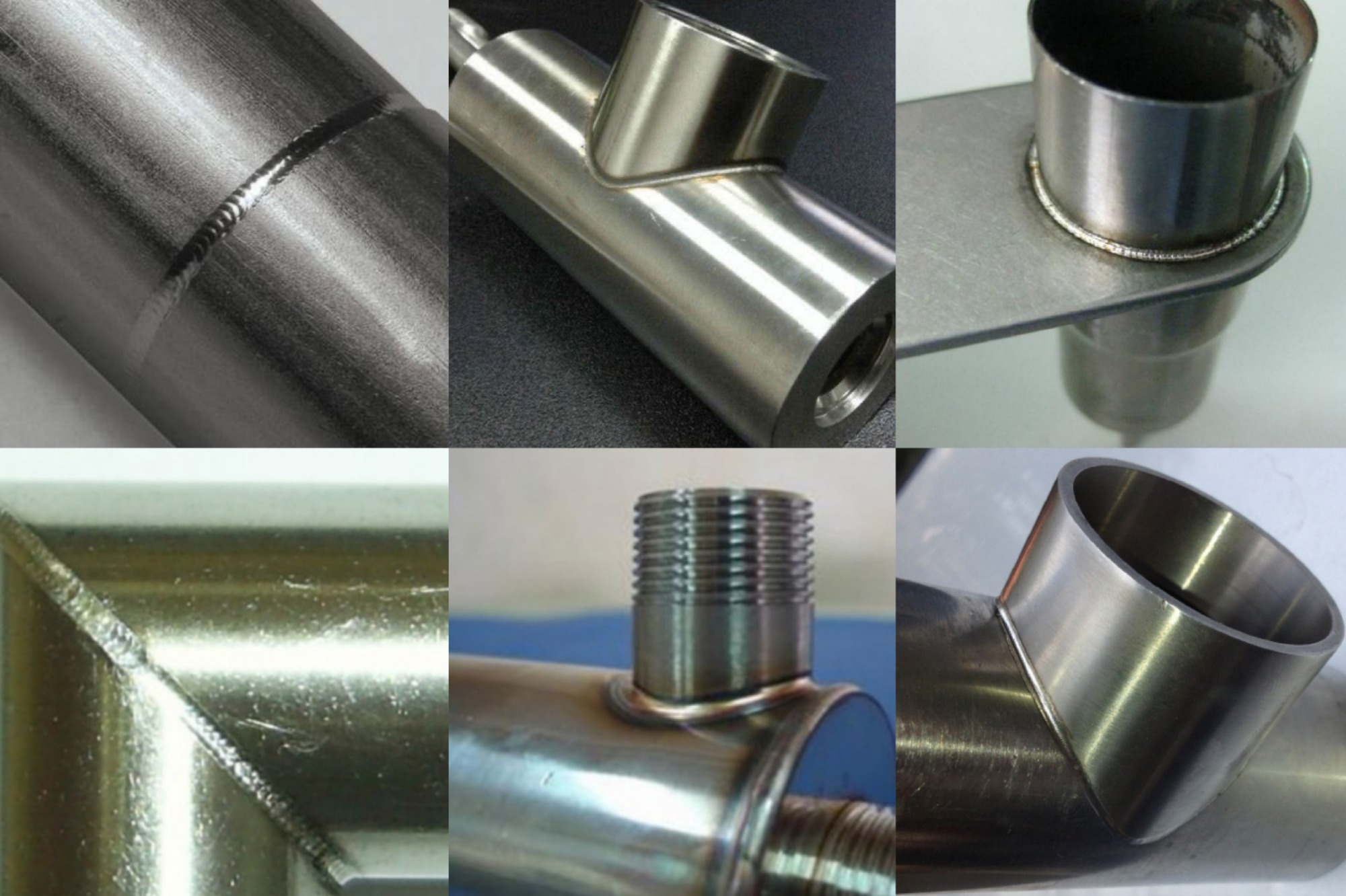

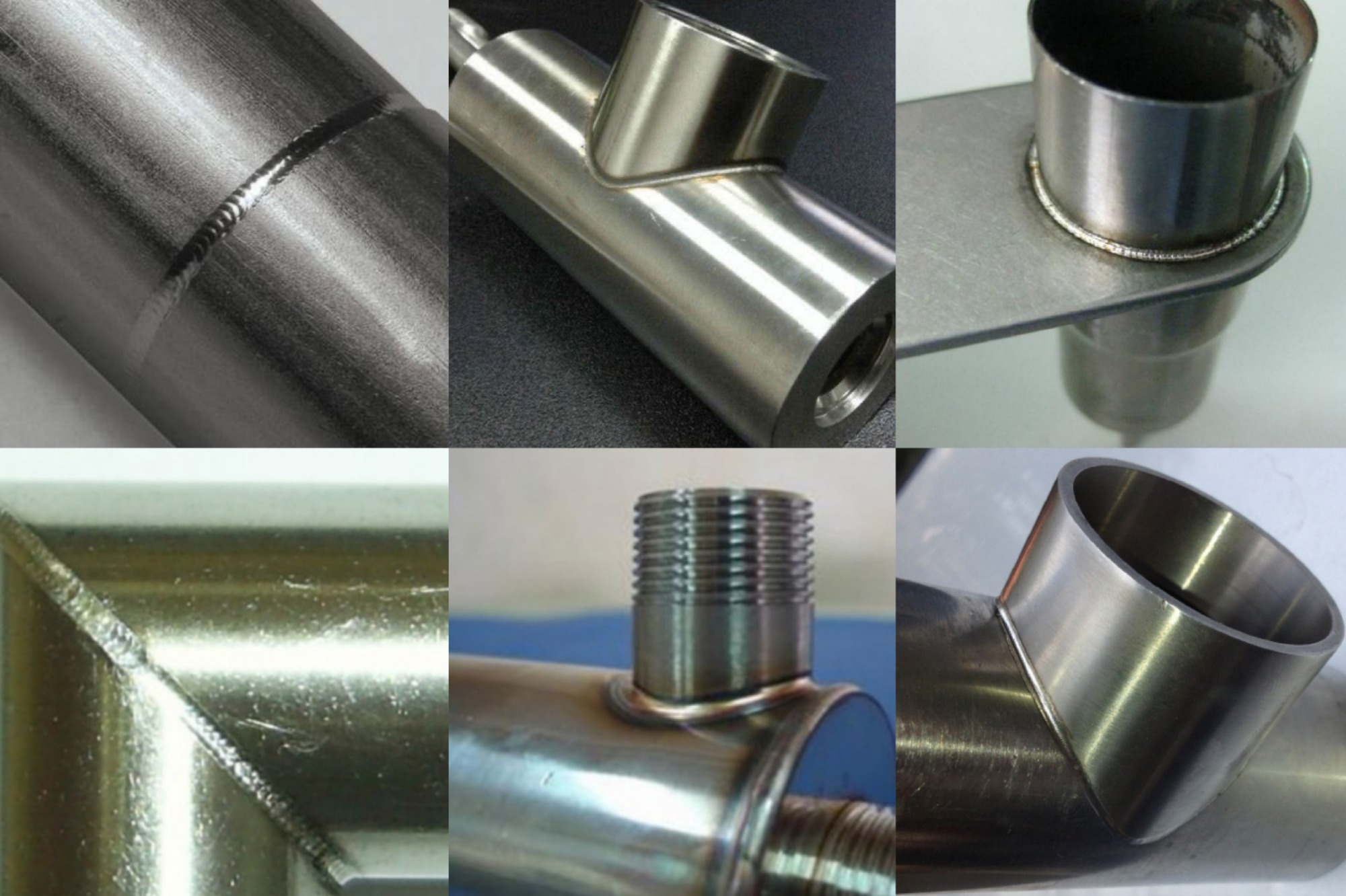

Application & Sample

With the development of laser technology, fiber laser cutting machine has replaced traditional processing methods with its high efficiency and flexibility, and has become more and more widely used. At present, the main industries are: sheet metal processing industry, advertising production industry, agricultural machinery industry, kitchen utensils industry, automotive industry, aerospace, etc.