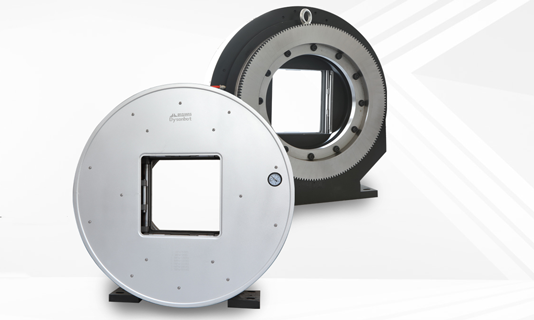

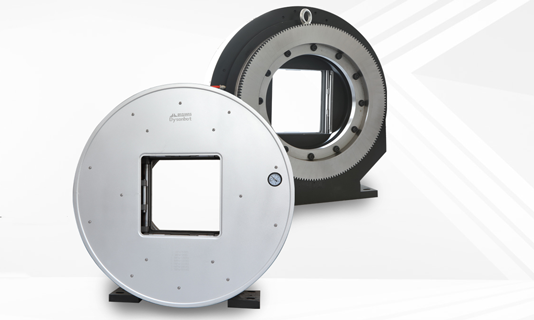

Pneumatic chuck, extending the transmission structure and improving the running stability. Automatic centering to ensure cutting accuracy. One-click clamping, fast speed. Professional small tube cutting chuck, high speed and higher processing efficiency

Professional Rotary

The segmented automatic support prevents the sagging and deformation of the pipe, ensures the cutting accuracy and prolongs the service life.

According to the diameter of the pipe, the support height is automatically adjusted, which is suitable for cutting all pipes.

The rotating power of the chuck adopts the helical rack and pinion transmission system, which has high coincidence, low noise, longer service life and more stable transmission.

Wireless Control

Wireless control handle, free control of chuck pressure, simple operation, reasonable structure, stable work and durable.

Precitec or Raytools auto-focus laser head,World brand and quality.

The software automatically adjusts the focal length to complete rapid perforation and cutting of sheets of different thicknesses.

It is more friendly to those with 0 experience, and the operation is simple, convenient, fast and accurate.

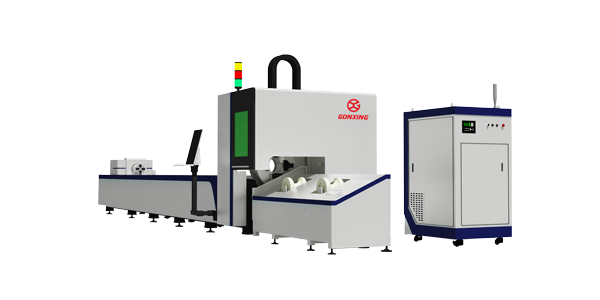

Machine Bed

The structure of the bed is welded with high-strength steel pipes, and there are reinforcing ribs in the pipes to increase the strength and toughness of the bed.

The whole bed is subjected to 3 welding processes to make the welding seam firmer. The stress relief heat treatment is carried out at 800 ℃ within 24 hours after welding. After taking it out, it is naturally cooled for many days to relieve stress and make the bed more durable and not deformed.

Cypcut Control System

CYPCUT control system is an excellent laser cutting control system, which integrates design, output and processing control. One software can complete the whole process from design to processing.

Rich functions, simple operation, suitable for various processing occasions

Automatic Lubrication System

Fully automatic lubrication system, high efficiency, no pressure relief, compact structure, no manual operation, regular and quantitative automatic oil supply, to ensure that the machine can work stably and efficiently.

Technical Parameters

| Model |

GX-6024T |

| Laser Power |

1000W/1500W/2000W/3000W,ect |

| Working Size |

6000mm |

| Positioning Accuracy |

±0.03mm |

| Repositioning Accuracy |

±0.02mm |

| Max Acceleration |

1.2G |

| Max Movement Speed |

60m/min |

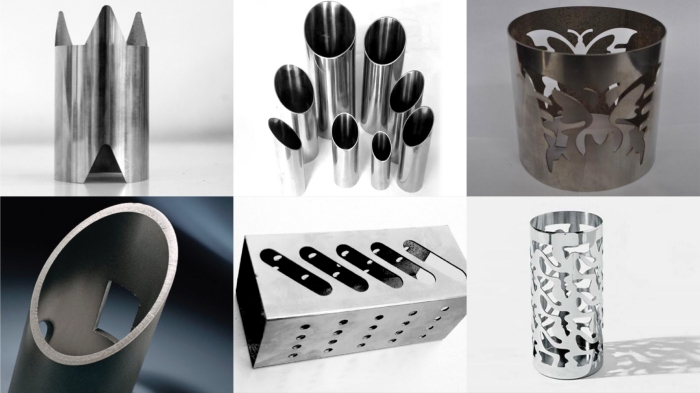

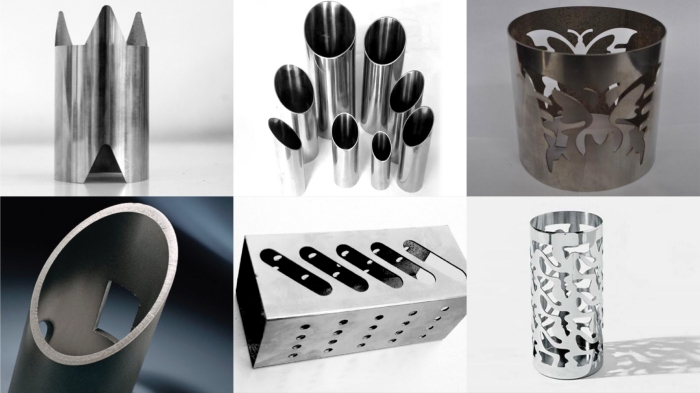

Application & Sample

With the development of laser technology, fiber laser cutting machine has replaced traditional processing methods with its high efficiency and flexibility, and has become more and more widely used. At present, the main industries are: sheet metal processing industry, advertising production industry, agricultural machinery industry, kitchen utensils industry, automotive industry, aerospace, etc.