1. Fine processing and efficient cutting of electronic processing parts

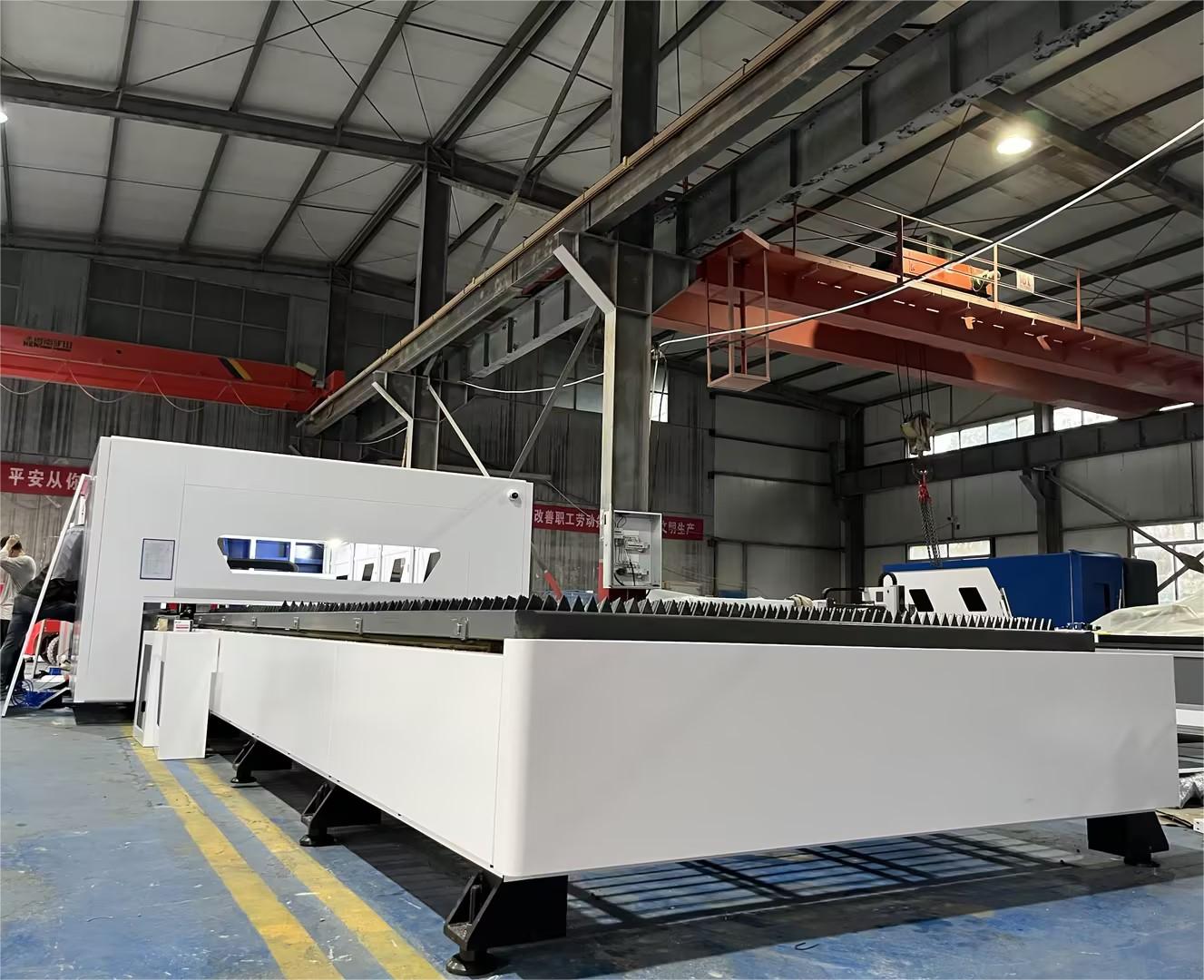

Most of the products are small and micro materials. The traditional cutting method is gradually eliminated by the market because it cannot achieve fine processing. In order to ensure the machining accuracy of complex workpieces, this puts forward extremely high requirements on the machining accuracy of the equipment. Laser cutting equipment can cut localized areas of material accurately and quickly. It has the characteristics of high cutting accuracy, fast speed, good quality and small heat affected zone of the workpiece. It is the first choice for processing metal materials.

2. Cost saving and easy maintenance compared with other cutting

In terms of equipment, laser cutting equipment can save more production costs for users. Traditional metal processing adopts contact processing method, the technology is not advanced enough, the operation process is complicated, the processing accuracy is difficult to guarantee, the workpiece has burrs, and the kerf is large. The laser cutting machine replaces the traditional cutting knife through photoelectric conversion technology, and realizes high-efficiency processing in a non-contact way; the computer control system equipped with professional cutting software does not need to use molds for cutting, supports the cutting of complex workpieces, can shorten the production cycle, and reduce the cost of use for users, Convenient equipment maintenance.

3. Mass production, convenient and fast

Due to the cumbersome operating procedures of traditional cutting equipment, the production speed is slow and the efficiency is low. Generally, large order processing cannot be accepted. However, laser cutting equipment has strong dynamic performance and can maintain stable precision and high production efficiency during large-scale processing.

In summary, the reason why the laser cutting machine can become the mainstream technology development direction of modern metal processing is that it can achieve high-efficiency processing while ensuring extremely high cutting accuracy and speed, and improve the production efficiency of metal processing.

As a manufacturer of intelligent high-end laser equipment, GX Laser provides innovative laser technology and advanced laser equipment for the metal processing industry.please click on our website’s online customer service, or add whatsapp: +8617660102273

GXLASER cutting machine: A Powerful Tool for Modern Manufacturing

GXLASER cutting machine: A Powerful Tool for Modern Manufacturing

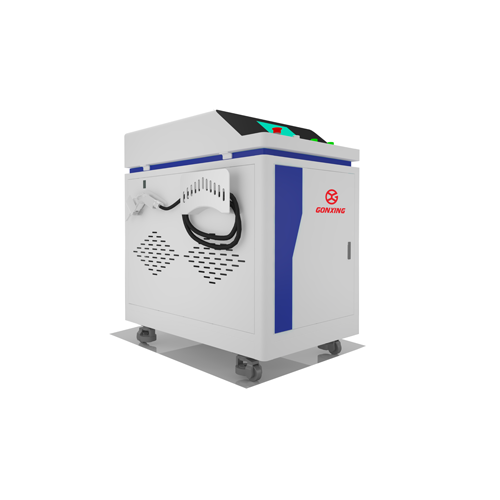

GXLASER Welding Machine: the Leader of Modern Welding Technology

GXLASER Welding Machine: the Leader of Modern Welding Technology

Comprehensive Analysis of GXLASER marking machines: Performance, Advantages and Market Prospects

Comprehensive Analysis of GXLASER marking machines: Performance, Advantages and Market Prospects